FreedomMachinist

Finally riding a big boys bike

Hello.

for my newly aquired Columbia Mod57 (Thanks Jeff / Rust'n Grease) I'd be happy to get some advice.

When turing the cranks, I can hear dirt/sand from the bottom bracket - so the main bearings need to be cleaned.

How do I disassemble the crank shaft ?

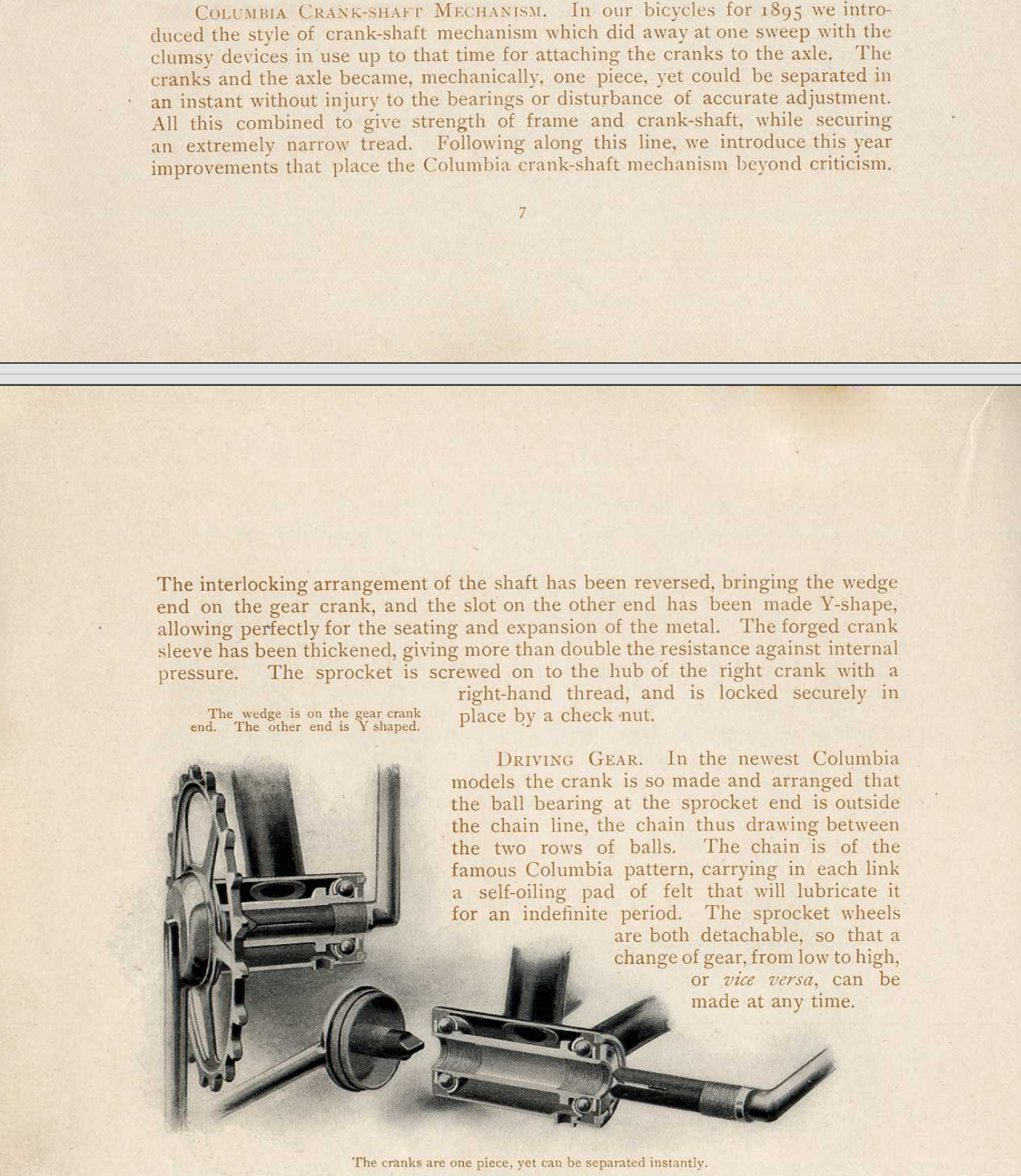

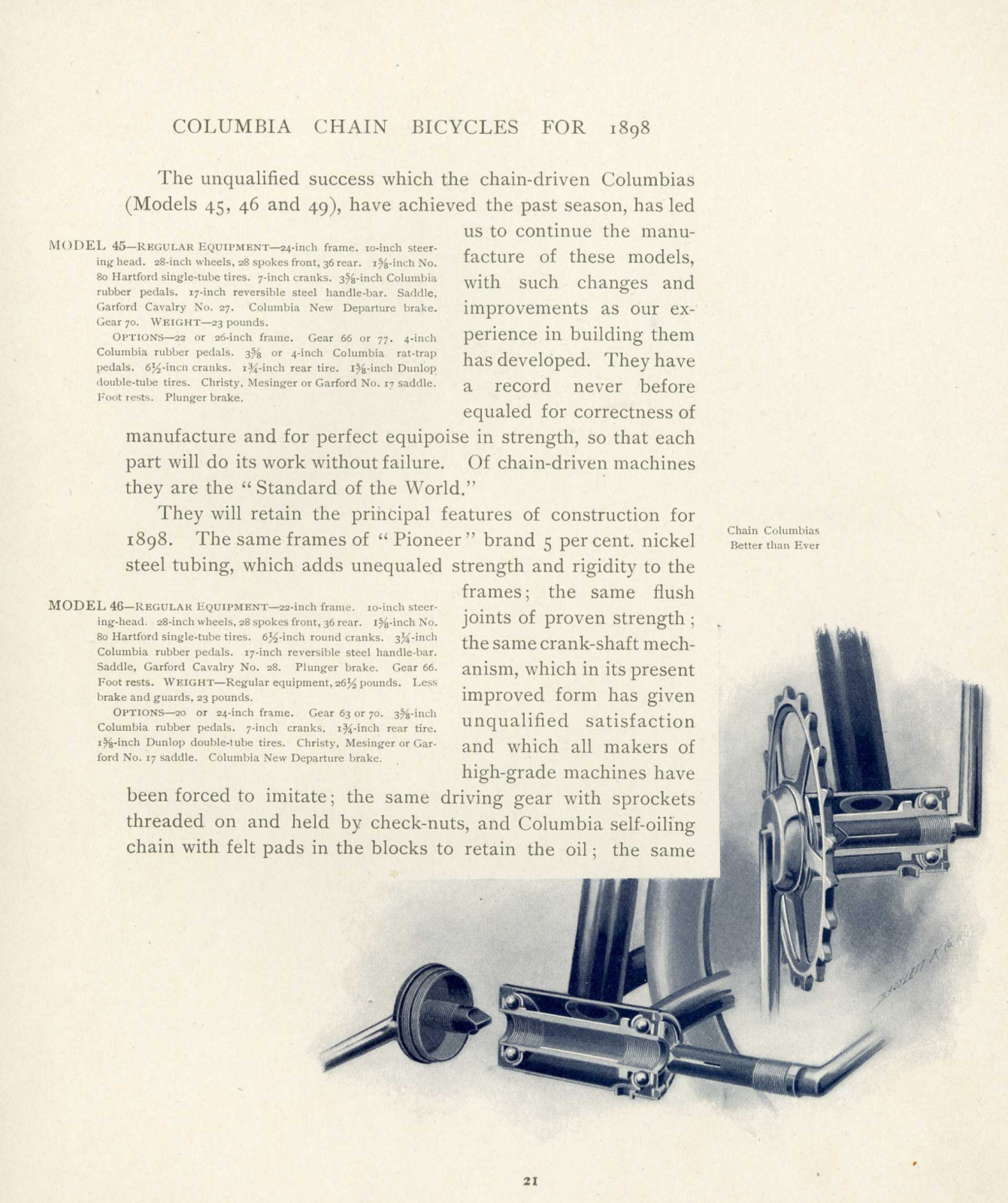

Here is a view from the 1897 and 1898 catalog (the 1899 doesn't show the assembly, but I think they had it still in 1899).

I have the cup on the right side open (here in the caatalog right side, photo below left side). This cup seems to set the play of the bearings - The cup cannot be screwed out any further, because it is blocked by the crank arm.

So: I need to separte the crank arm shaft !

I guess this is a similar principal as on my Lenox:

The threaded cups in the frame adjust the play of the balls which rest on cones. The cones are not separated the usual way but both cones are incorporated into one long sleeve.

The sleeve is runing independent of the crank shaft (You may adjust the play of the bearing without any crankarms mounted yet).

The crank arms are split in the center and, on the Lenox, they are held together by a long screw, going from one side to the other. The shaft is cut under 45°, so the halves expand when the clamping screw is tightend and thus press against the bearing shaft - works great.

With Columbia, the story seems different: No long axial screw to clamp both sides together, but threads on the bearing sleeve and pedal shaft sbring both sides together.

Since a wedge on one side fits into a Y-slot on the other side, the shaft will expand and press against the sleeve.

That must mean that :

This is my theory how the disassembly works - can anybody confirm that ?

Of course I have tried to turn it open, but nothing moves. A portion of the "lock tunel" has already been damaged by someone else, and I took the damage a little further

The BB was soacked with WD40 for a few days already ... Usually I'd use some heat at this point , but I cannot really heat up the area that needs to get hot

Any advice would be welcome

Thanks

Jochen

P.S.: By the way: 1899 is correct, isn't it ? It is a Model 57 with porcubine hubs and a lock nut as seatpost clamp, which is one year only, I believe....

for my newly aquired Columbia Mod57 (Thanks Jeff / Rust'n Grease) I'd be happy to get some advice.

When turing the cranks, I can hear dirt/sand from the bottom bracket - so the main bearings need to be cleaned.

How do I disassemble the crank shaft ?

Here is a view from the 1897 and 1898 catalog (the 1899 doesn't show the assembly, but I think they had it still in 1899).

I have the cup on the right side open (here in the caatalog right side, photo below left side). This cup seems to set the play of the bearings - The cup cannot be screwed out any further, because it is blocked by the crank arm.

So: I need to separte the crank arm shaft !

I guess this is a similar principal as on my Lenox:

The threaded cups in the frame adjust the play of the balls which rest on cones. The cones are not separated the usual way but both cones are incorporated into one long sleeve.

The sleeve is runing independent of the crank shaft (You may adjust the play of the bearing without any crankarms mounted yet).

The crank arms are split in the center and, on the Lenox, they are held together by a long screw, going from one side to the other. The shaft is cut under 45°, so the halves expand when the clamping screw is tightend and thus press against the bearing shaft - works great.

With Columbia, the story seems different: No long axial screw to clamp both sides together, but threads on the bearing sleeve and pedal shaft sbring both sides together.

Since a wedge on one side fits into a Y-slot on the other side, the shaft will expand and press against the sleeve.

That must mean that :

- the threads are counterwise (one left one right hand thread).

- the bearing sleeve has to be locked to mount the arms , by inserting a bar through a hole in the bottom bracket - The bar is stuck into a slot on the sleeve and keeps the sleeve from rotating.

- then both pedal arms have to be screwed out evenly, by turning the pedals in the same direction as you do when you brake.

This is my theory how the disassembly works - can anybody confirm that ?

Of course I have tried to turn it open, but nothing moves. A portion of the "lock tunel" has already been damaged by someone else, and I took the damage a little further

The BB was soacked with WD40 for a few days already ... Usually I'd use some heat at this point , but I cannot really heat up the area that needs to get hot

Any advice would be welcome

Thanks

Jochen

P.S.: By the way: 1899 is correct, isn't it ? It is a Model 57 with porcubine hubs and a lock nut as seatpost clamp, which is one year only, I believe....

Last edited: