Metacortex

Wore out three sets of tires already!

Referencing this topic showing an upside-down serial number stamp (and I've seen and heard of several others http://thecabe.com/forum/threads/someone-please-explain-this-photo-for-me.85709/

http://thecabe.com/forum/threads/someone-please-explain-this-photo-for-me.85709/

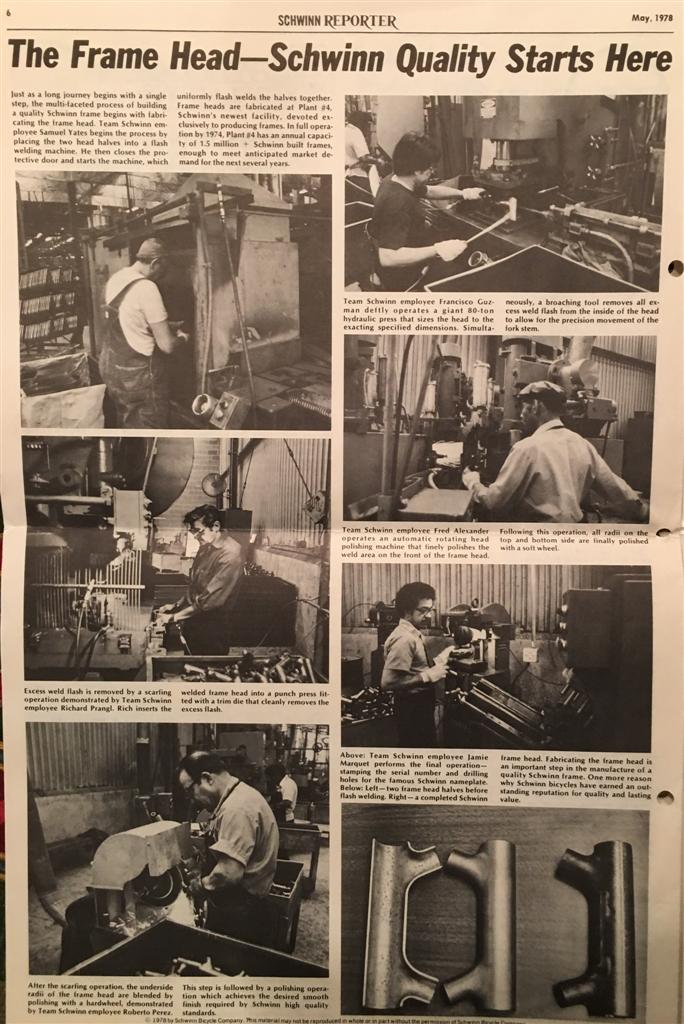

I just acquired the May 1978 Schwinn Reporter filling in a gap in my collection and finally have located definitive documentation about how and when the serial numbers were stamped in the frame manufacturing process:

As the article states the serial number was stamped as part of the very last operation in the headtube manufacturing process (along with drilling the badge holes). Considering the shape of the headtube and the stamping process you can see how easy it would have been to stamp some upside-down.

Thinking about this further, I've never seen or heard of a fillet-brazed bike with an upside-down serial number. The fillet-brazed bikes would have had this stamping and drilling done on a bare tube with no protrusions (meaning no up from down other than the serial number location). Since in that case the serial number would be the only indication of up or down and since they were subsequently hand-brazed it is no wonder you never see a fillet-brazed bike with an upside-down serial number. Comments anyone?

I just acquired the May 1978 Schwinn Reporter filling in a gap in my collection and finally have located definitive documentation about how and when the serial numbers were stamped in the frame manufacturing process:

As the article states the serial number was stamped as part of the very last operation in the headtube manufacturing process (along with drilling the badge holes). Considering the shape of the headtube and the stamping process you can see how easy it would have been to stamp some upside-down.

Thinking about this further, I've never seen or heard of a fillet-brazed bike with an upside-down serial number. The fillet-brazed bikes would have had this stamping and drilling done on a bare tube with no protrusions (meaning no up from down other than the serial number location). Since in that case the serial number would be the only indication of up or down and since they were subsequently hand-brazed it is no wonder you never see a fillet-brazed bike with an upside-down serial number. Comments anyone?

Last edited: